biomass pellet machine accessories

Among the accessories of biomass pellet machines, wearing parts refer to those parts that are easily worn or damaged during long-term use and need to be regularly inspected and replaced.

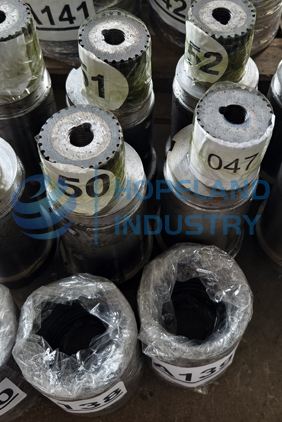

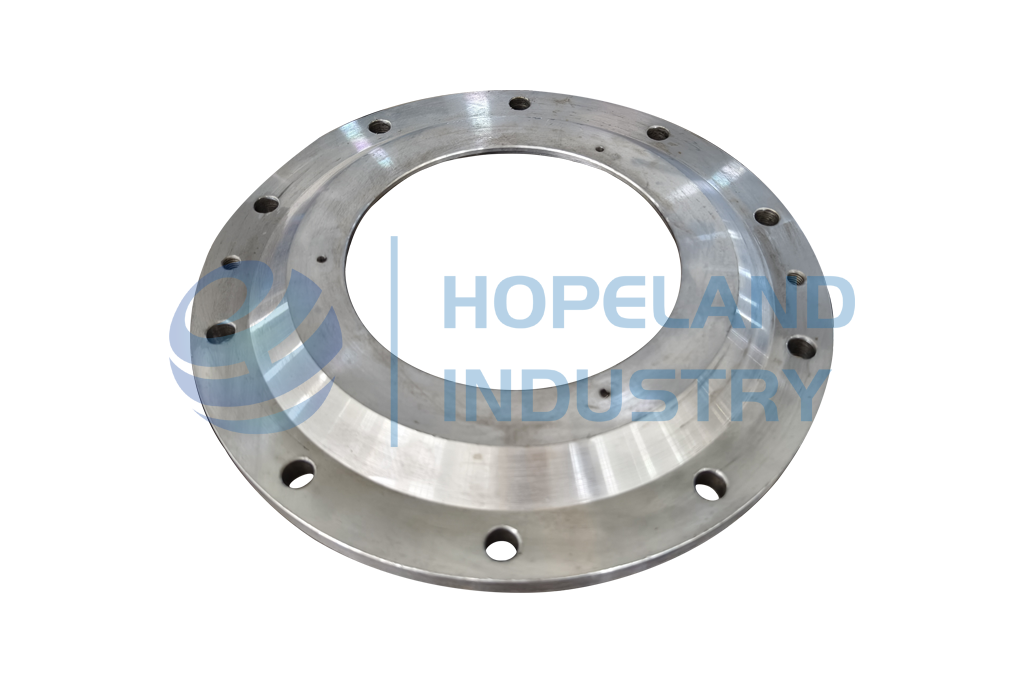

Commonly used wearing parts include: molds, roller skins, roller assemblies, bearings, etc. Among them, roller skins and molds are the most commonly used wearing parts.

The pellet machine molds of different materials and models can be customized, which are suitable for pellet machines of various manufacturers.

The pellet machine molds of different materials and models can be customized, which are suitable for pellet machines of various manufacturers.

Pellet machine mould

High-strength wear-resistant roller assembly with customizable materials and dimensions for stable extrusion molding.

Precision-engineered roller skin made of chrome-molybdenum alloy steel (HRC58-62), ensuring perfect alignment with ring dies to enhance pellet mill stability and roller service life.

High-precision wear-resistant roller skin manufactured from heat-treated 40Cr alloy steel (HRC58-62), featuring precision-machined inner surfaces for optimal ring die contact, significantly improving pellet mill performance and roller durability.

Heavy-duty eccentric shaft with customizable specifications for precise roller pressure adjustment and stable operation.

High-performance roller bearings with heavy-load design, offering exceptional wear and heat resistance (up to 250°C) for extended equipment lifespan.

Reinforced roller cover with precision sealing system to maintain bearing lubrication and prevent particulate contamination, ensuring operational reliability.

Precision-machined oil seal spacers for accurate shaft sealing, preventing lubricant leakage and external contamination.

Bearing spacers designed to maintain optimal clearance, distribute axial loads, and protect against premature wear.

Advanced lip seal technology creates effective oil film barriers, preventing lubricant leakage while blocking external contaminants.

FaQ

We’ve compiled answers to common customer questions below. For further assistance, contact us directly – we respond within 24 hours.