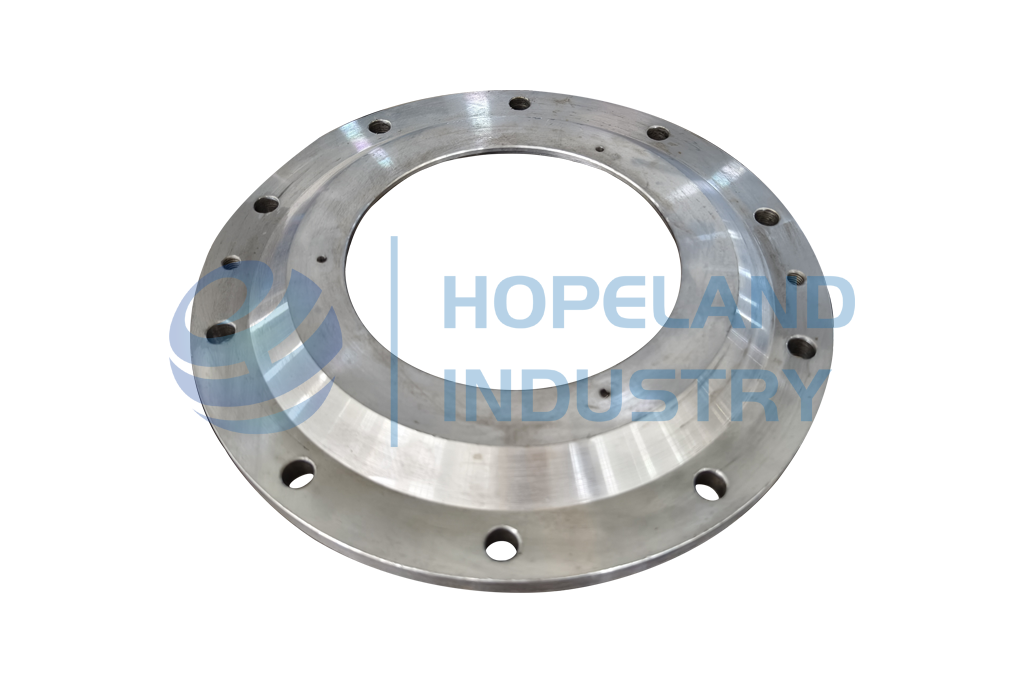

Common Wear Parts in Biomass Pellet Mills – Sealing Rings

Functions of the Sealing Ring

Preventing Leakage: Prevents raw material, grease, or dust from escaping through the gap between the ring die and the roller.

Reducing Wear: Protects the contact surface between the ring die and roller, reducing direct metal-to-metal friction.

Maintaining Pressure: Ensures stable pressure within the pressing chamber, improving pellet forming efficiency.

Common Causes of Damage

Wear: Long-term friction with the ring die/roller causes gradual thinning or cracking of the material.

High-Temperature Aging: High temperatures generated during biomass pellet pressing reduce the elasticity of the sealing rings, making them brittle.

Improper Installation: Offset or uneven tightening can lead to localized stress concentrations.

Impurity Intrusion: Metal shavings or hard objects in the raw material can scratch the sealing surface.

Insufficient Lubrication: Dry friction exacerbates seal ring wear.

Replacement Criteria

Visible damage: such as cracks, gaps, or severe deformation.

Seal failure: Powder or oil leakage, or unstable pressure during operation.

Regular replacement: It is recommended to inspect and replace the ring die every 500-1000 tons of pellets produced or every 3-6 months (the specific frequency should be adjusted based on actual usage intensity).

Maintenance and Installation Tips

Cleaning: Thoroughly clean any residual material and oil from the ring die cavity before replacement.

Lubrication: Apply a high-temperature grease (such as molybdenum disulfide) during installation to reduce initial wear.

Symmetrical tightening: Tighten the bolts evenly to avoid uneven stress on the seal ring.

Regular inspection: During weekly shutdowns, inspect the sealing surface for indentations or signs of wear.

Other Related Wear Parts

Seal ring failure may damage the following components, so it is recommended to inspect them simultaneously:

Ring die: Check for even wear on the die bore.

Press roller: Check for integrity of the bearing seals.

Press roller: Check for integrity of the bearing seals.

Lubrication system: Check for unobstructed oil flow to avoid accelerated wear of the seal ring due to oil starvation.