Common Wear Parts in Biomass Pellet Machines – Molds

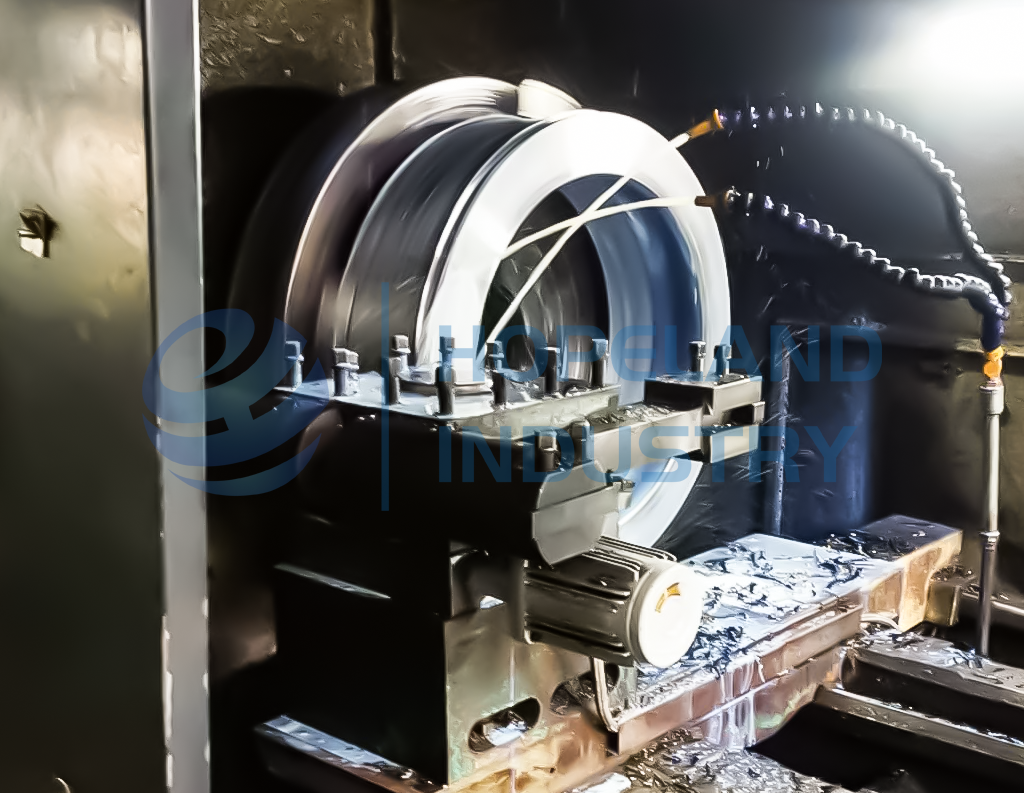

During the operation of a biomass pellet machine, the mold, as a key component, directly impacts pellet quality and equipment efficiency. As a common wear part, the selection of its material and compression ratio are crucial.

Mold Material: Wear Resistance and Compatibility Determine Service Life

Mold material is fundamental to its durability. Currently, mainstream materials include:Alloy Steel

High hardness and strong wear resistance; smooth surface, resulting in high-quality pellets; requires regular lubrication and maintenance.

Stainless Steel

Excellent corrosion resistance, suitable for acidic or humid raw materials; smooth surface, resulting in high-quality pellets; and extended service life.

Experts advise that material selection should match the raw material characteristics to avoid a one-size-fits-all approach. For example, improper use of high-silicon raw materials can accelerate wear.

Die Compression Ratio: Scientific Matching Improves Production Efficiency

The die compression ratio refers to the ratio of aperture to effective thickness and is a core parameter for pellet forming:Definition and Impact

A higher compression ratio results in higher pellet density and greater hardness, but also increases equipment load. A too low compression ratio results in loose pellets and poor formation.

Adjustment Strategy

If the formation rate is insufficient, the compression ratio can be appropriately lowered to increase production, but this must be balanced with die life. For large-scale equipment, a stable compression ratio is recommended to ensure long-term operation.

Experts warn

Selecting the wrong compression ratio can easily lead to machine blockage, motor overload, and even die breakage. It is recommended to customize the die selection based on raw material characteristics and equipment parameters, or to obtain technical debugging and optimization from the manufacturer.

Conclusion

The die is the “heart” of the biomass pellet machine. The appropriate selection of its material and compression ratio is directly related to production line stability and economic efficiency. Industry experts recommend regular inspection of die wear, proper lubrication, and timely replacement of suitable die for efficient and sustainable production.